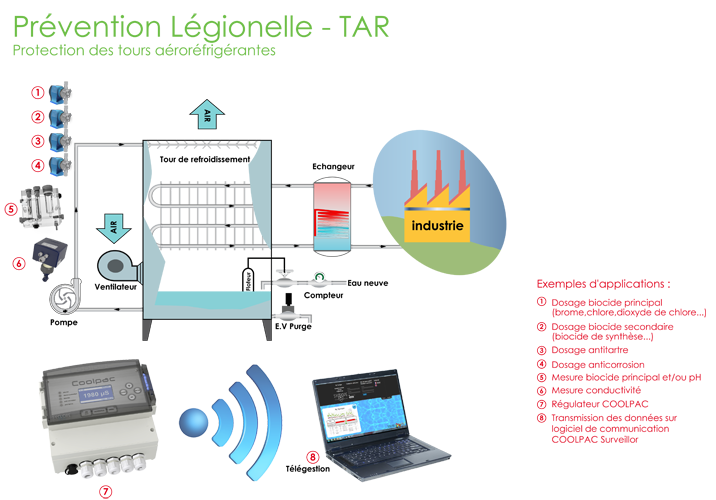

Management of cooling towers

The COOLPAC range has been specially designed for water quality management of cooling towers and to fight against legionella.

PLUS FOR YOUR USE

COOLPAC offers many assets and advantages

TECHNICAL FEATURES

Application

- Cooling towers

Tower deconcentration management

- Volumetric (cumulative volume + purge time)

- Conductivity: graphite or inductive probe

Management of 2 biocides

- 2 types of biocides

- Biocide dosage :

– continuous

– programmable timer

– timer with regulation (oxidizing biocide)

– injection by timer, up to 16 timers - Injection cycle with pre-purging and locking

- In case of purging, injection of priority biocides

- Guaranteed biocide injection times

Management of a dispersant product and a corrosion inhibitor product

- Injection mode :

– continuous

– cyclic

– by purge time ratio

– volumetric in relation to the filling

Tower pH management

- Automatic injection by programmable pH

- Choice of regulation direction (pH+ or pH-)

Measuring inputs

- 1 conductive conductivity input

- 1 input 4-20 mA for continuous measurement: oxidizing biocide

- 1 4-20 mA temperature input for conductivity compensation

- 1 input 4-20 mA for inductive conductivity or pH sensor

Dry contact inputs

- 1 pulse counter input

- 1 remote control input

- 1 level contact input

Relay outputs

- 1 relay 230 V deconcentration control

- 1 relay 230 V biocide control A (oxidizer)

- 1 relay 230 V biocide control B

- 1 relay 230 V corrosion inhibitor control

- 1 relay 230 V dispersing control

- 1 relay 230 V alarm or pH control

Analog outputs

- 2 programmable 4-20 mA outputs (control or data transfer)

Power supply

- 230 VAC – 50/60 Hz – 5 A

We are here to support you …

Do you have any questions? Need a diagnosis, recommendations? Need a documentation, an estimate ? The SYCLOPE team is at your disposal …